TDK Serial Design

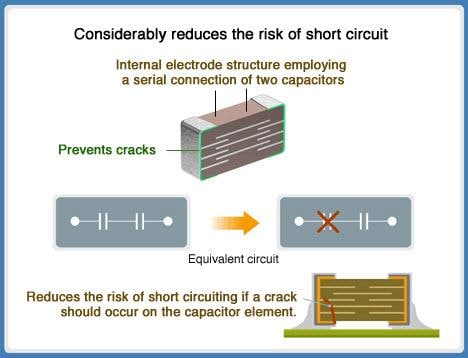

TDK Serial Design is a type of MLCC with the highest safety, adopting dual safety designs for crack occurrence prevention and short circuit occurrence prevention. The conductive resin layers are inserted in the terminal electrodes, and the resin electrode layers absorb stress applied by flex or thermal expansion of the board to prevent crack occurrences. The internal electrodes then adopt a special structure, which is equivalent to a serial connection of two capacitors. This structure reduces the risk of short-circuiting if a crack occurs in the capacitor element. The TDK CEU series is also compliant with AEC-Q200 and can be used for automotive applications.Features

- Fail-safe function employing a serial connection of two capacitors inside one product prevents unexpected short circuit accidents

- Improved resistance to bending, drop impacts, thermal shock, and heat cycle of the board

- The conductive resin absorbs external stress, protecting solder joints and components

Applications

- Automotive applications (EPS, ABS, EV, HEV, LED lamps, etc.)

- Smoothing circuits, DC-DC converters, LED/HD lamps

- Application in environments with severe temperature changes, countermeasure against piezoelectric effect

- Circuits directly connected to 12V or 24V battery lines or circuits requiring enhanced safety

- Countermeasure against high-frequency noise (radio noise), surges, or electrostatic discharges (ESD)

Safety can be easily achieved due to the internal structure connecting 2 capacitors in series

When regular products are replaced with Serial design (the CEU series) in power lines carrying a large current, safety can be easily enhanced due to their dual fail-safe function. Since just one Serial design (the CEU series) product can realize safety design which usually employs a serial connection of two regular products, mounting areas, or mounting costs can also be reduced.

Regular Products Replaced with Serial Design

Serial Design Short Circuit Countermeasures

Published: 2019-08-05

| Updated: 2024-02-21